Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

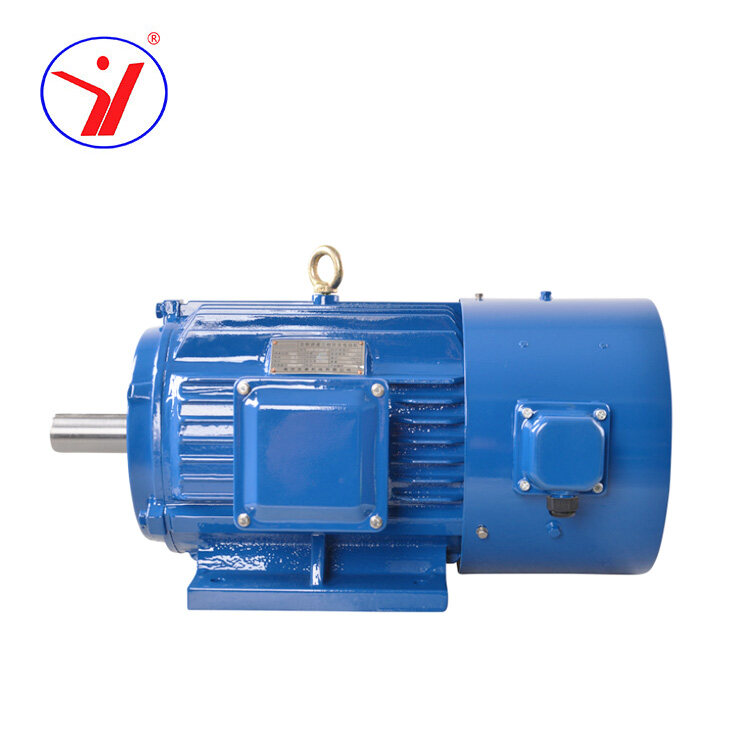

The YVF series comprises YVP frequency-controlled motors (0.55 kW 30 kW) with 100% copper coils and high-precision rotors. Featuring IP54/IP55 protection, it offers durability in iron-cast housing. Based in Fujian, China, the factory provides customizable OEM/ODM solutions with a one-year/1000-hour warranty, ensuring enhanced efficiency compared to ordinary motors.

Product Specification of the YVF series

|

Parameter |

Details |

|

Motor Type |

YVP three-phase frequency-controlled asynchronous motor |

|

Output Power |

0.55 kW 30 kW |

|

Frame Size |

IEC 80 200 |

|

Rated Voltage |

380V |

|

Frequency |

50 / 60 Hz |

|

Protection Level |

IP54 / IP55 |

|

Insulation Class |

B / F |

|

Cooling Method |

ICO141 |

|

Working Duty |

Continuous (S1) |

Product Features and Advantages of the YVF series

1. 100% Copper Coil: Utilizes brand-new national standard copper wire for enhanced efficiency, stability, and safety.

2. Seiko Bearing: Manufactured from high-strength carbon steel material, ensuring a prolonged lifespan.

3. High Precision Rotor: Incorporates a brand-new national standard rotor, undergoes multiple precision machining, and passes dynamic and static balance tests.

4. Iron-casting Motor Housing: Provides durability and resistance to impacts; boasts high mechanical strength with reduced vibration and noise.

FAQ

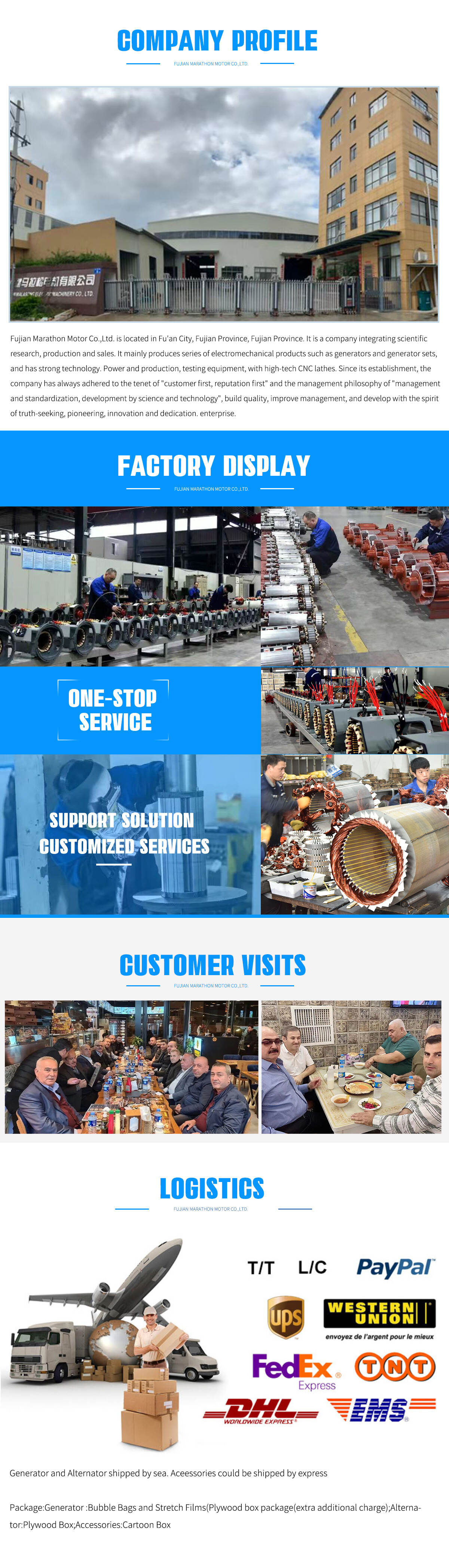

Q: Where is your factory?

A: Located in Fu’an City, Fujian Province, China.

Q: Is customized service available?

A: Yes.

Q: Do you support OEM and ODM?

A: Absolutely.

Q: How long is the product warranty?

A: The warranty covers one year or 1000 working hours, whichever occurs first.

Q: Does your packaging ensure product safety?

A: Our plywood box packaging ensures the utmost product protection.

Q: What details are required for an accurate quote?

A: Specify the desired power capacity and any specific engine brand preferences.

Difference Between Variable Frequency Motors and Ordinary Motors

When considering variable-frequency motors versus ordinary motors, the primary distinction lies in their operation with different degrees of harmonic voltage and current. Operating motors with non-sinusoidal voltage and current, especially with sine-wave PWM inverters, results in certain harmonics. High-order harmonics notably increase stator copper loss, rotor loss, iron loss, and additional loss, significantly impacting rotor copper (aluminum) loss.

Asynchronous motors, operating at synchronous speeds near the fundamental frequency, experience larger rotor losses due to high-order harmonic voltages. Additionally, considering the skin effect-induced copper losses, these motors produce excess heat, reduce efficiency, and diminish output power. For instance, an ordinary three-phase asynchronous motor under a non-sinusoidal power supply from a frequency converter typically sees a temperature rise of 10%–20%.