Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

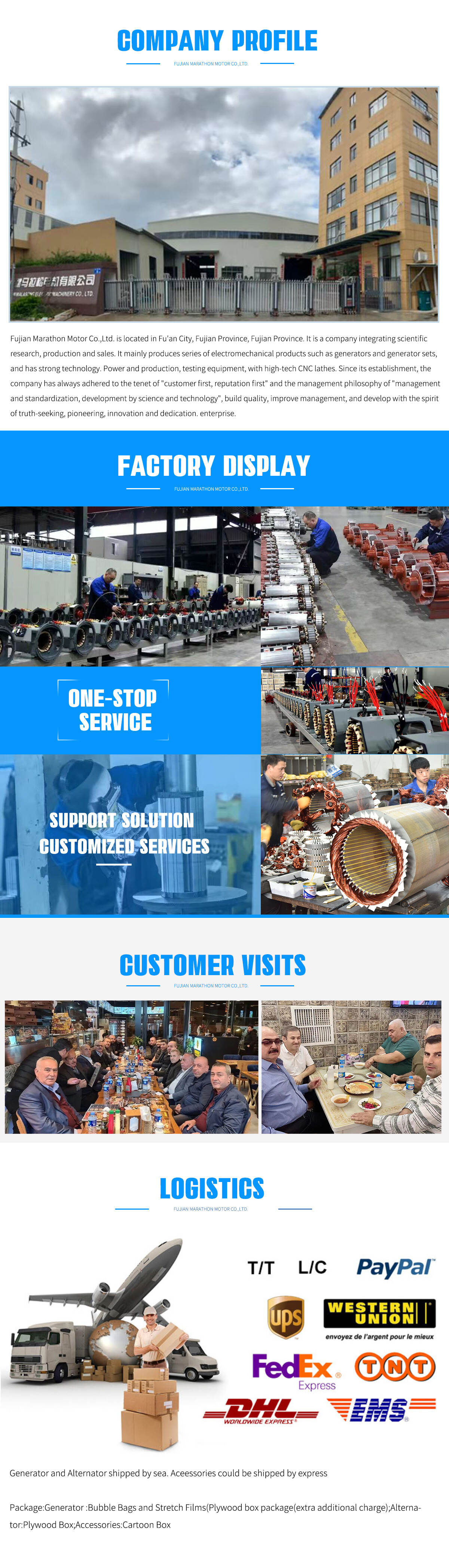

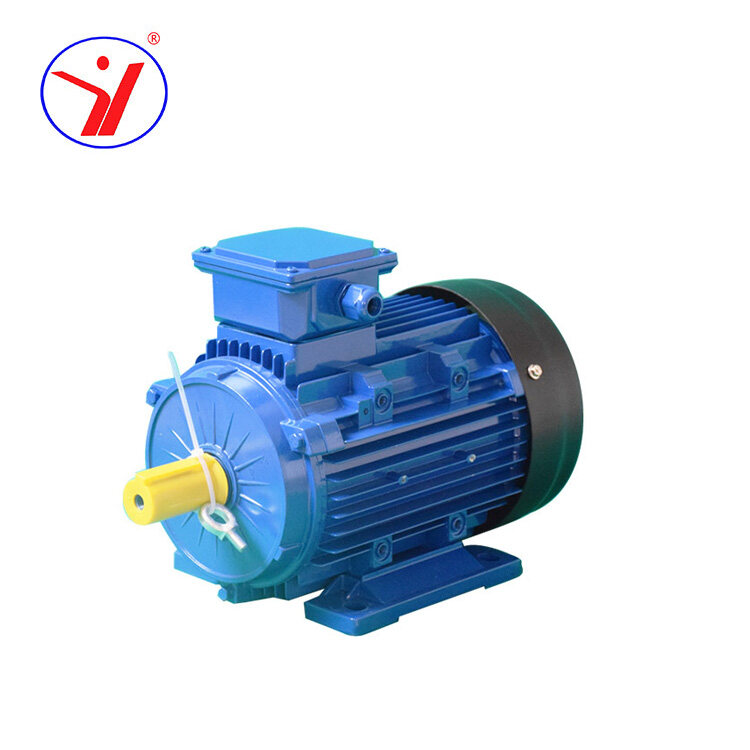

Introducing the MS Motor Series—a cutting-edge range of 3-phase asynchronous motors renowned for their superior performance and reliability. Engineered with precision, these motors combine low noise, low vibration technology with a simple yet robust design, making them ideal for diverse applications. Experience efficiency, durability, and seamless operation with the MS Motor Series.

Product Specification of the MS Motor series

|

Product Detail |

Description |

|

Motor Type |

3 phase asynchronous motor |

|

Output Power |

0.06 kW 18.5 kW |

|

Ambient Temperature |

-15℃~40℃ |

|

Altitude |

Not more than 1000m |

|

Rated Voltage |

380V, optional between 220V ~ 760V |

|

Rated Frequency |

50Hz, 60Hz |

|

Protection Level |

IP54, IP55 |

|

Insulation Class |

B/F |

|

Cooling Method |

IC411 |

|

Working Method |

S1 |

|

Connection Method |

Y connection for 3kW and below, △ connection for 4kW+ |

Product Features and Advantages of the MS Motor series

1. Low noise and low vibration:

Engineered for reduced noise and vibration, ensuring a smooth and stable operation.

2. Simple Structure:

The MS series motor boasts a straightforward structure, facilitating easy installation and maintenance. It stands as a reliable choice for applications prioritizing efficiency and long-term performance.

3. Varnished Wire:

Constructed with 100% B/F insulation-class copper wire.

Production Process of the MS Motor series

1. Material Selection:

Stator and Rotator are crafted with premium Wugang 800 material.

2. Winding:

Stator and rotator winding processes.

3. Insulation:

Painting to achieve Insulation Class H standards.

4. Assembly:

Motor assembly procedures.

5. Finishing:

Canopy painting.

6. Testing:

Full load testing was conducted.

7. Packaging:

The product is packaged securely in a plywood box.

Understanding the Coil

The coil stands as an integral part of the motor winding, comprising either single-turn or multi-turn insulated wire. In a motor winding, multiple coils come together. The two straight sections of a coil set within the core slot are termed the "effective side" of the coil, responsible for electromagnetic energy conversion. Meanwhile, the coil's exposed portions at the core slot ends form a bridge, connecting the effective sides. These bridge sections don't partake in electromagnetic energy conversion; however, longer ends lead to increased energy loss. The wires that introduce current into the coil are known as motor leads. The count of turns within each coil is termed its "number of turns."