Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Our Brush DC Motor Series stands out as a pinnacle of engineering excellence. Designed for optimal performance, these motors combine durability with precision, catering to diverse industrial needs. With their versatility, efficiency, and cutting-edge features, they promise reliability and longevity, ensuring seamless operations across various applications.

Product Specification of the Brush DC Motor series

|

Parameter |

Specification |

|

Motor Type |

DC Electric Motors and DC Machine |

|

Output Power |

1/4, 1/2, 1, 2, 3, 5, 7.5, 10HP |

|

Armature Voltage |

0-80, 0-195 |

|

Excitation Voltage |

100, 110/220 |

|

Torque(KG*CM) |

10, 20, 40, 80, 120, 200, 300, 400 |

|

Rated Current(A) |

1.2, 3, 4, 10, 15, 24, 35, 42 |

|

Duty |

S1 |

|

Start Torque |

125% above |

|

Cooling Method |

IC411 |

|

Adjustable Speed Range |

30-1800RPM |

|

Insulation Class |

B/F |

|

Excitation Method |

Separate Excitation |

|

Temperature |

-5℃-50℃ |

Product Features and Advantages of the Brush DC Motor series

1. Excellent Motor Performance: The series brush separately excitation HP DC motor offers excellent motor performance with its simple operation, easy maintenance, low noise, and low vibration.

2. Versatility: This direct current motor is versatile and can be used for acceleration, deceleration, or constant speed driving of various industrial machinery that require constant output, constant torque, and square torque loads.

FAQ

Q: What is your MOQ?

A: Our MOQ is 1.

Q: What is your delivery time?

A: 10–30 DAYS.

Q: What are the payment methods you accept?

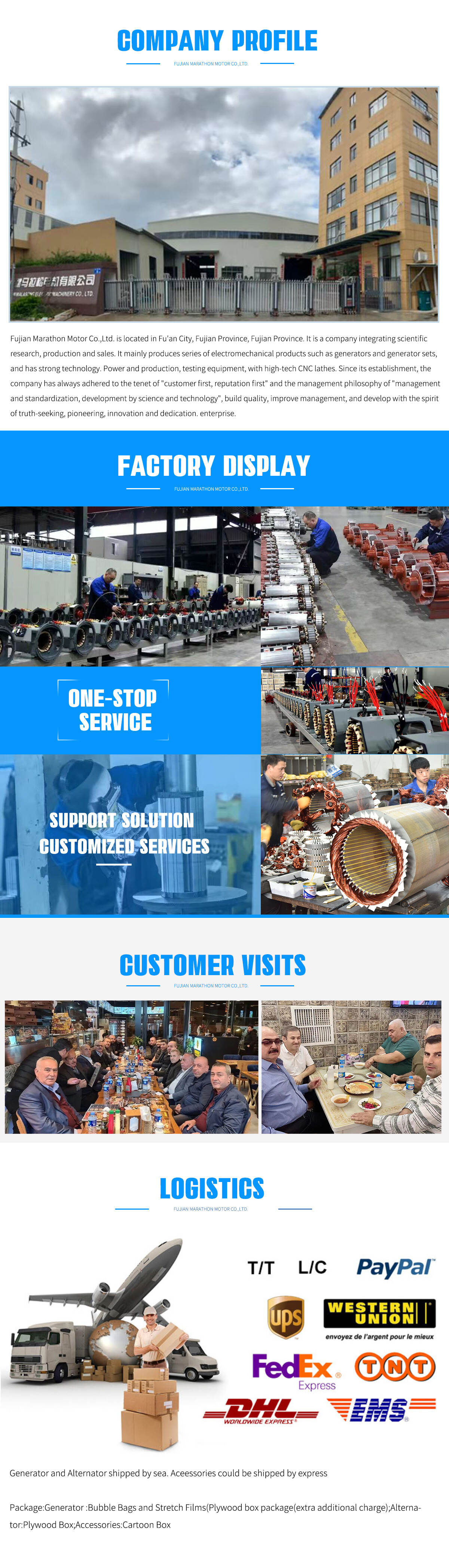

A: T/T L/C and Western Union.

Q: How do you guarantee the quality of your products?

A: We use only the best materials to ensure the highest quality.

How Does DC Motor Start?

DC motors have specific starting characteristics due to the low resistance and inductance of the armature circuit coupled with rotor mechanical inertia. Upon switching on, the initial armature speed and corresponding back electromotive force are minimal, leading to a surge in starting current, which can be 15-20 times the rated current. This can cause grid interference, machinery impact, and commutator sparking.

To mitigate this, a variable resistor can be connected in series within the armature circuit, gradually decreasing resistance as the motor starts. This method, known as series resistance starting, limits the starting current to a permissible value. While it's effective for small and medium-sized DC motors, it's not ideal for conventional or larger motors due to its high energy consumption. However, certain applications, like frequent tram startups in large cities, employ this method for its simplicity and efficiency.