Maximizing Efficiency: A Comprehensive Guide to Brushless Alternators

In the realm of power generation, efficiency is paramount. Among the various components driving efficiency in power systems, the alternator holds a pivotal role. Today, we delve into the world of brushless alternators and explore strategies to maximize their efficiency. Whether you're a company seeking optimal sourcing or a brushless alternator efficiency wholesaler aiming to enhance your offerings, this guide is your roadmap to brushless alternator efficiency excellence.

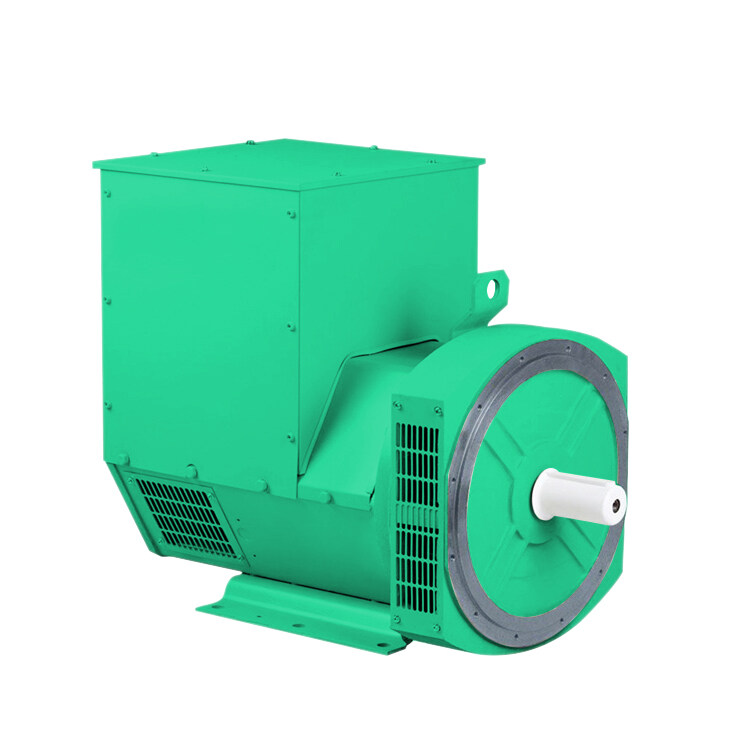

Understanding Brushless Alternators

Brushless alternators have revolutionized the field of power generation with their superior reliability and reduced maintenance requirements compared to brushed alternators. At the core of their operation lies electromagnetic induction, a principle discovered by Michael Faraday in the early 19th century. This phenomenon occurs when a conductor, in this case, the stator windings of the alternator, is exposed to a changing magnetic field, inducing an electromotive force (EMF) and thus generating electricity.

Unlike their brushed counterparts, brushless alternators eliminate the need for carbon brushes and slip rings, which are prone to wear and require regular maintenance. Instead, they utilize solid-state electronic components, such as rectifiers and voltage regulators, to control the output voltage and frequency. This design not only enhances reliability but also contributes to improved efficiency by minimizing mechanical losses associated with brush friction.

The Importance of Efficiency

Efficiency is a critical metric in the realm of power generation, influencing both economic viability and environmental sustainability. In simple terms, efficiency measures how effectively an alternator converts input mechanical power, usually from an engine or turbine, into electrical power. It is expressed as a percentage, with higher values indicating less wasted energy and more effective power conversion.

For brushless alternator efficiency wholesalers and companies alike, maximizing efficiency offers numerous benefits:

- Cost Savings: A more efficient alternator requires less fuel or input power to produce the same output, resulting in lower operational costs over the lifespan of the equipment.

- Environmental Impact: By reducing fuel consumption and emissions, efficient alternators contribute to a smaller carbon footprint, aligning with sustainability goals and regulatory requirements.

- Enhanced Performance: Efficiency optimizations often go hand in hand with improvements in power density, voltage regulation, and transient response, leading to better overall performance and reliability.

Factors Influencing Efficiency

Achieving peak efficiency in brushless alternators requires careful consideration of various design and operational factors:

1. Design Optimization: Manufacturers employ advanced simulation tools and optimization techniques to fine-tune the design of alternator components, such as the rotor, stator, and voltage regulation circuitry. This iterative process aims to minimize losses due to resistance, hysteresis, and eddy currents while maximizing magnetic coupling and flux density.

2. Material Selection: The choice of materials significantly impacts the efficiency and performance of brushless alternators. High-conductivity copper is preferred for stator windings due to its low resistance and superior thermal properties. Likewise, selecting magnetic core materials with high permeability and minimal hysteresis losses enhances magnetic flux conduction and reduces energy dissipation.

3. Cooling Systems: Efficient heat dissipation is essential for maintaining optimal operating temperatures and minimizing losses in brushless alternators. Cooling systems, such as air or liquid cooling, help dissipate excess heat generated during operation, ensuring consistent performance and prolonging the lifespan of critical components.

4. Control Strategies: Advanced control algorithms play a crucial role in maximizing efficiency under varying load conditions. By dynamically adjusting excitation currents, phase angles, and voltage regulation parameters, smart control systems optimize alternator performance in real-time, responding to changes in load demand and operating conditions.

Strategies for Brushless Alternator Efficiency Wholesalers

As a brushless alternator efficiency wholesaler specializing in brushless alternators, you play a vital role in facilitating efficiency improvements across the industry. Here are some strategic initiatives to consider:

1. Collaborative Product Development: Partner with manufacturers and engineering firms to co-develop custom alternator solutions tailored to specific market segments or application requirements. By leveraging collective expertise and resources, you can introduce innovative products that set new benchmarks for efficiency and performance.

2. Value-Added Services: Differentiate your offerings by providing value-added services such as installation support, training workshops, and maintenance contracts. Position your company as a trusted partner that delivers comprehensive solutions, not just products, thereby fostering long-term customer relationships and loyalty.

3. Market Segmentation: Identify niche markets or emerging industry sectors where brushless alternator efficiency is a critical differentiator. Tailor your marketing and sales strategies to address the unique needs and pain points of these segments, positioning your products as the ideal solution for maximizing efficiency and productivity.

Case Studies in Efficiency Excellence

Real-world examples illustrate the tangible benefits of brushless alternator efficiency in diverse applications:

1. Telecommunications Infrastructure: A telecommunications company deployed high-efficiency brushless alternators to power remote cell towers and communication nodes. By reducing fuel consumption and maintenance downtime, the brushless alternator efficiency company achieved significant cost savings while ensuring uninterrupted service delivery in remote and off-grid locations.

2. Data Center Operations: In the fast-paced world of data centers, uptime and energy efficiency are paramount. By integrating brushless alternators with advanced power management systems, data center operators can minimize energy waste and optimize resource utilization, driving down operational costs and enhancing environmental sustainability.

Conclusion

In conclusion, brushless alternator efficiency represents a convergence of technological innovation, engineering expertise, and market demand. The brushless alternator efficiency wholesalers, companies, and sourcing specialists all play pivotal roles in advancing the efficiency agenda, from product design and manufacturing to distribution and customer support.

By embracing a holistic approach that encompasses design optimization, material innovation, and smart control strategies, we can unlock new levels of efficiency and performance in brushless alternators. Together, let's harness the power of innovation to build a greener, more sustainable future for generations to come.